Students Set the Future in Concrete

The average toothbrush has 2,500 bristles.

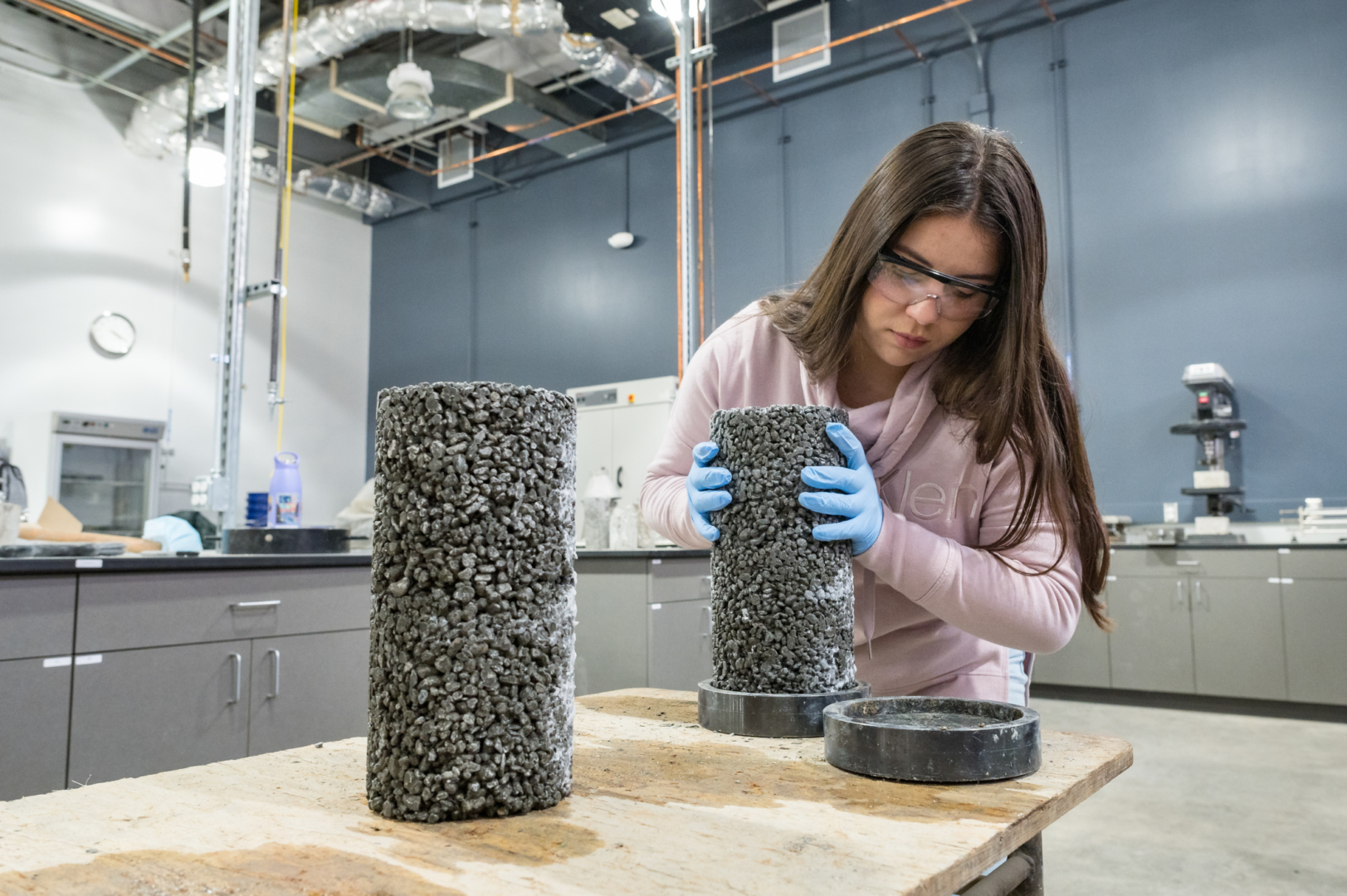

Aubrey Miller should know. She’s stripped hundreds of thousands of them out of their plastic heads in the last

year as she experiments with reinforcing her concrete mixes in a more sustainable way. For months, the concrete industry management major sat pulling the flexible, porous fibers out of the used brushes in clumps, and then meticulously measured them by volume and folded them into her mortar mixtures. Once the concrete cured, she’d conduct a variety of compression, flexural, and shrinkage tests to see if her bristles were building a better batch.

“I wanted to do something that actually made a difference,” said Miller, who’s graduating this spring. “Based on my research, it’s been highly successful. This could actually be used in real-life practices, and I think that, above all, has been the most fulfilling thing I’ve done so far in college.”

As a high school student, Miller had no idea that concrete was even a career field, let alone a $200 billion industry.

But a presentation at her school one day from Chico State’s Concrete Industry Management (CIM) Program caught her attention. When she heard about its 100 percent job-placement rate, she decided instantly that it was the path for her.

In her first class, the students toured a plant for premade concrete, known as ready-mix, and as Miller donned a

hard hat and watched the trucks cart tons of swirling concrete off to shape the world, it cemented her decision.

“I could picture myself working there,” she said. “Ever since, I have loved concrete, learning about concrete, being around concrete. It’s so much more complicated than people think—so much that can go wrong with it and so much that can go right.”

Chico State’s CIM program is one of just five in the United States and benefits from industry partnerships and alumni support to help it thrive. In addition to learning the science of the evolving concrete industry, students also learn how to lead in the boardroom through the integration of business administration courses.

Graduates often go on to jobs in project and operation management, sales and marketing, field engineering, quality control, and lab research. Others work directly with concrete as specialists, plant managers, or researchers.

“When someone wants a career that is hands-on, involves working with people, requires multiple skills

to be successful, and deals with a product that makes an outstanding building, home, bridge, whatever, it’s tough

to beat concrete,” said Dana Davis, president of Teichert Materials and one of the program’s co-founders. “Regardless of what your career interests are, you can find it here and in a product that is vital to our everyday lives.”

According to the concrete industry, no material is consumed more in the world except water. As a building block that dates back beyond ancient Roman times, it’s made by mixing cement and water with sand, gravel, and crushed stone known as aggregate to create a product that offers unsurpassed durability and strength once it hardens.

From home foundations and towering skyscrapers to ribbons of highway and hollow pontoons that form the base of floating bridges, concrete is everywhere, touching everyone’s life.

With this in mind, Davis joined Doug Guerrero (Honorary Doctorate of Humane Letters, ’17) and many other concrete industry leaders from across the country in conversations 25 years ago about the need to attract more talent and a steady workforce, especially at the leadership level. Soon, they had identified a few universities across the nation to start programs, including Chico State in 2007 to serve the Western United States.

The program enrolls about 80 students each year. It has a national reputation for work-ready graduates, outstanding applied concrete-related research, and invaluable community service.

Supporting its success are the CIM National Steering Committee and Chico CIM Patrons, which include 46 local, regional, national, and multinational concrete industry firms as well as 27 generous individuals who make personal yearly contributions and do some recruiting of their own.

Senior Bryson Bowen credits his uncle, CIM Patron Scott Humphrey, for pointing him toward the program when he was struggling to pick a major.

“I said, ‘Yeah, you’re right, concrete is everywhere.’ I had just never thought about it,” Bowen said. “I knew coming out of high school I wanted to contribute to society in some way, and knowing we need infrastructure in a large quantity is really cool.”

“Concrete is a very interesting material because it can be hard as a rock but it also has this state where it’s plastic and you can move it around. It has unlimited potential,” he continued.

Graduating this spring, Bowen has accepted a job with building materials giant CEMEX, where he will explore a range of positions and ultimately have his choice. He’s likely to select ready-mix, he said, because he loves working so closely with concrete itself, but he’s interested in managerial roles. During college he was challenged to create a startup company—planning everything from the structure and expenses to planning the yard design and calculating employee needs—and it taught him so much about the facets of the industry.

But no experience in college, he said, can match the National Precast Concrete Association’s (NPCA) student competition, where students are asked to take an existing construction project and plan every aspect themselves. After participating on Chico State’s winning team in 2021, he led the team as captain this year to take first place once again.

With a team of some of his most promising classmates, Bowen worked with an industry advisor twice a week, drafted a 35-page report, and gave a sales pitch to the convention audience, explaining how the team would use preformed box culverts to build a pedestrian underpass in Colorado under a state highway. It was the perfect application, he said, of what they learn in the classroom in a real-life environment.

“This is just a program unlike any other,” he said. “It’s not really known, but if you do know about it, there are so many opportunities. Other majors find a lot of competition in the job market and have to hunt for employers, but as such a unique program, the job offers basically come rolling in for our CIM grads.”

Graduating CIM major Casey Cowern is headed to Dome Construction—her choice of four job offers she landed early last fall. She was drawn to the company because it had a family feel and the opportunity to immediately engage with projects, just like her undergraduate experience.

At Chico State, she has partnered with faculty on research projects, helped lead her peers as a student assistant in the lab, and had the chance to explore her own interests, which include cement alternatives.

She also worked two summer internships in the industry. The first was as a project engineering intern for a student housing project at University of California, Santa Cruz, where Cowern hosted site safety briefings, coordinated subcontractor meetings, and observed concrete pours and heavy machinery in real-time. The following summer she worked in San Jose as an estimating intern in preconstruction, calculating everything from demolition to site concrete, preparing bid packages, and issuing new construction drawings.

With Dome, she’ll be a project engineer—a level of career success she dreamed of long before college.

“My parents just made it to high school. I realized I didn’t want to be in the same situation as them, living paycheck to paycheck. I wanted education to further my life and create better opportunities,” she said.

Coincidentally, Cowern shares her passion with her great-grandfather, who she never met but learned early in her studies had been a leader in the concrete industry in the late 1800s and early 1900s. She’s read some of his books and is deeply inspired by her connection.

“It’s crazy to see how the concrete industry has achieved so much more technology and innovation—and I get to be a part of that,” she said.

She’s also making changes from a demographic perspective—as a woman in an industry where less than 20 percent of employees are women. Cowern spent the last two years as president of Chico State’s Women in Concrete Club. Throughout the pandemic and virtual learning, she was able to help organize résumé workshops, practice interviews, and networking with alumni. In fall 2021, the club hosted Women in Concrete Day on campus, where seven alumni came to talk to students about what to expect and how to lead once they graduate.

“Women don’t think this is a workforce they can be in and some feel very scared to enter a job industry where it’s very male dominated,” she said. “I look at it as a pro for me. I’m able to show that women have different characteristics to bring to the table. We are trying to beat that gender bias.”

With her passion for concrete, Cowern has become a lead ambassador for CIM, traveling to high schools to entice the next generation of students to follow her path. One of her recruits is Yanetli Navarro-Hernandez, a junior who decided she wanted to work in the construction industry at 10 years old.

As soon as she arrived at Chico State, she poured herself into CIM—joining the American Concrete Institute (ACI)

and Women in Concrete Clubs, interning with a Los Angeles company pouring the concrete foundation for SoFi Stadium, working part-time with a ready-mix company in Chico, helping Miller with her research, and becoming a student ambassador herself.

Navarro-Hernandez is especially passionate about opportunities to engage with her community. Chico State’s CIM program has a long history of civic engagement, whether rebuilding the Caper Acres playground in Bidwell Park, refreshing concrete in school courtyards, or rebuilding homes lost to the Camp Fire in partnership with Habitat for Humanity. As the incoming president of the student chapter of ACI, she’s hoping to partner with Butte College on an upcoming playground project.

“Not only do we apply what we are learning in the program but we get to do something for our community,” she said.

Now 19, when she finishes her coursework next spring, she’ll be the youngest graduate in the program’s 15-year history.

“I’m starting to get a taste of everything,” she said. “I’ve always known I was going to be in a management position, but I’m thinking project management because I like to see things from the ground up and I like to take charge.”

It was that kind of passion that drew Professor Mohammed Albahttiti to the program in 2017. During his interview, the students grilled him on how he could help enhance their education and teach them the latest the industry had to offer.

“We have students who are interested in learning. It’s not just to get an education or a degree,” he said. “They want to be experts—they want to be leaders.”

He tries to provide every opportunity he can. He is eager to further his understanding of how materials behave under extreme events, the durability of concrete infrastructures, and the structural stability of fiber-reinforced concrete, as well as new technologies like 3-D printed concrete.

So when he and a group of partners received $3.9 million in federal funding to establish a Rural Railroad Safety Center in collaboration with four universities across the United States, he hired six CIM and civil engineering students to assist him with the project. Four of them will head to Kansas State this summer to test the durability of reinforced concrete for the project.

He also encourages them to have fun. Last year, Albahttiti’s students competed for bragging rights to build the most impressive tensegrity table, which creates the illusion of a concrete tabletop defying gravity, and this spring, they are making working treasure chests. Last year, a group of students made a skateboard, and a few years earlier, it was a functioning electric guitar, which now hangs in the associate dean’s office.

“You can do anything with concrete,” he said. “And every year, I challenge them to come up with new possibilities.”

For Albahttiti, who fell in love with concrete as a 14-year-old working to build his family home in the United Arab Emirates, it’s a dream career come true. When he’s not in the classroom or mentoring students in the lab, he can often be found in the hallway or sitting in his office advising students on their hiring offers or how to decide which of many internships to accept. In return, they often call him after graduation, looking for interns for their companies or to invite him to their weddings.

To date, more than 170 graduates of Chico State’s CIM program are leading concrete teams across the world. At Teichert Materials and at industry tradeshows, Davis sees them regularly—across construction, ready-mix, aggregates, and so many other concrete-related fields.

One of his favorite parts about being a CIM Patron is interacting with students, whether at competitions, in the classroom at Chico State, or as interns.

“The energy level just goes up a whole other notch when you start talking to these students who come into the program with expectations to have a great career and contribute to the betterment of society,” he said.

“And when you see them excel in their jobs and at these competitions, it just gets your heart pulsing a little more. We are indeed going to have a bright future.”

With the $1 trillion federal infrastructure bill signed into law in November 2021 and the critical need for more housing across all markets, it is anticipated demand for graduates in this field will only continue to grow, Davis said. And with more scholarships to offer than students to award them to, there is opportunity for any student who is interested.

The Patrons also provide guest lectures, sponsor field trips, and provide other financial support. In 2016, a $1 million gift from Dennis Murphy (Civil Engineering, ’94; Honorary Doctorate of Humane Letters, ’18) helped renovate Chico State’s Concrete Lab to a state-of-the-art facility with new equipment and expanded workspaces. An additional $400,000 from the CIM Patrons the following year further enhanced opportunities for project-based learning.

“[The CIM Patrons] are critical to our mission and our students’ success,” Albahttiti said. “And they like to hire our students. I always get calls, ‘Do you have more?’ At conventions and conferences, people walk up to me and tell me—unsolicited—how impressed they are with our students.”

Jerry Xiong (CIM, ’18) has been working with Jensen Precast as a quality control supervisor since graduation and recently earned his certification as a Master Precaster—the first program alumnus to be awarded the prestigious designation.

As he prepared for his certification, his training included aspects on how each part of the field operates, from aggregate to engineering. As a Chico State CIM graduate, he said, he had a major head start.

“CIM doesn’t just teach you about concrete—it’s a little bit of everything when it comes to understanding control and design, engineering, manufacturing, quality,” Xiong said. “And it helps you to become a leader. Straight out of college I landed as a quality control supervisor.”

As an undergraduate, he tried out several majors in engineering before finding his home in CIM. Raised in a Hmong-speaking household in Marysville, he said there was not a word for “concrete” to explain to his family what he had finally chosen for a career.

“I thought, ‘Let me give it a try.’ And here I am, and I’m doing something different,” he said.

Xiong takes pride in knowing the projects he has a role in at Jensen are shaping the world, whether creating the foundational components for wastewater and water systems or helping underground electrical lines for wildfire prevention.

He’s also excited to be responsible for ensuring the quality of their products—recently earning a 100 percent-compliance rate in their National Precast Concrete Association Plant Audit—and finding innovative solutions for producing durable products and building a more sustainable environment.

“There are many barriers to break, old culture, old habits, but we have to learn from the deficiencies,” he said. “It takes a lot of courage to make a change, but at the end, it will pay off.”

Environmental sustainability continues to be a major challenge for the industry. With that in mind, cutting energy use and waste has become a big focus for the program—and a passion of CIM students.

“It’s important to me to create a better world,” said Miller, who presented her research last fall at the American Concrete Institute Convention—the only undergraduate among numerous graduate researchers.

Concrete typically has a certain percentage of manufactured fiber in it to reinforce it, and Miller’s research indicates toothbrush bristles are a more sustainable substitute. As a bonus, finding a new purpose for the discarded brushes also upcycles them into a value-added product that is necessary for everyday life, she explained. Using 4,000 pounds of used brushes donated by TerraCycle, she was able to conduct the first known study of its kind.

She’s been equally captivated by other research in the program, whether the integration of rice and walnut hulls, reimagined uses for recycled concrete, or integrating volcanic rock instead of cement.

Bowen, too, sees great promise in recycling. During an internship with Mathews ReadyMix, he worked with Albahttiti on trying to find a way to recycle the aggregate in concrete. Often, the mix trucks return with a volume of unused mix, and rather than discard it, they are hoping to find an alternate purpose. Other aspects of Bowen’s research worked to replace cement with a less CO2-emitting material and use alternative fuels to ignite the kilns that produce cement.

“If cement was a country, it would make up 6 percent of the world’s pollution,” he said. “We want the world to last

a long time and support generations in the future. And since concrete is not going anywhere, we need alternative sources of hydraulic material that can act as a binder and we need better fuels that can create the cement.”

Sustainability has been a hallmark of Albahttiti’s work as he and the students reshape the future of the industry. Whether building wildfire-resistant homes or considering artificial intelligence as a way to detect weakness in concrete, he finds opportunities to be innovative and encourages students to take a leading role as they enter the workforce.

“I truly believe that our graduates will lead the concrete industry and will be among the CIM Patrons of tomorrow,” he said.

The combination of technical classes and internship opportunities prepared students well for working in industry, Miller said. Whether practicing estimating and concrete testing, or learning about the chemistry of cement, she gained real-world skills that have immediate application.

In addition to her research, she’s been president of the ACI student club, worked in the college’s Student Success Center, competed—and won—at national competitions, worked as a student ambassador to bring new prospects into the program, and offered tutoring to her peers. And every summer, her internships further put her classroom experience into practice: testing concrete with a ready-mix company, working at an admixture systems business in Seattle and Portland, and doing independent sales with MasterBuilder Solutions.

At the World of Concrete convention this year, the industry named her the winner of the Bob Weatherton Award, reserved for students who have made the most of their CIM program.

Miller had her choice of jobs, and when she got an offer to start working part-time this spring, she was ready to jump right in. Since January, she has been flying to Minnesota every other week to work as a sales trainee in MasterBuilder Solutions’ admixture department, selling mixtures, fibers, and other products, as well as working as a service technician for customers—all while completing her degree.

“If you had told me four years ago that I was going to be where I am today, I probably would not have believed you,” Miller said. “It’s satisfying to know I personally took full control of my education and used it to every advantage.

A lot of people look at it like, ‘It’s just concrete,’ but if you start to look into it, it’s a mind-blowing opportunity.”

Give to CIM today! Help students grow professionally and ensure they have the resources to focus on their studies and extracurriculars.

Chico State CIM program thriving with solid industry support from Chico State College of ECC TV on Vimeo.